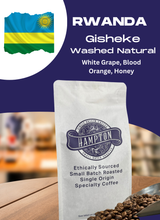

Rwanda

Gisheke Washed

White Grape, Blood Orange, Honey

This coffee presents a smooth mouthfeel that carries a vibrant and layered flavour profile. White grape notes offer a crisp, juicy brightness, complemented by the rich sweetness of orange. A gentle finish of milk chocolate rounds out the cup, adding a creamy, comforting depth.

Varietal: Red Bourbon

Information on the coffee

Gisheke is located in Nyamasheke District, and overlooks Lake Kivu. Almost half of the cherries received at Gisheke come by boat from Mushungwe Island. All the cherries from the neighbouring islands are delivered by boat to Gisheke, which is only accessible by water.

Gisheke’s geographic location makes it ideal for the processing and drying of naturally processed lots. This is due to the consistent wind flow that moves between two steep hills that lead towards Lake Kivu, Idjwi Island and the Democratic Republic of the Congo.

In Rwanda, Raw Material work alongside Muraho Trading Co. This partnership helps affiliate co-operatives increase their quality of production, fetch a higher price for their coffee, and introduce them to new markets. This will be a continuous work in progress in the coming years, as we gain a greater understanding of the particular challenges Rwandan coffee producers face.

Through this process they can develop a model that creates incentives which generate producer buy-in, all the while maximising impact. Raw Material supply coffee from across Muraho’s washing stations, which are located in the Nyamasheke, Gakenke, and Nyabihu regions of Rwanda.

All cherry is hand-sorted before a pre-pulp float, underripe or damaged cherry is removed, along with any foreign objects. Cherry is then floated in pre-pulping tanks removing any floaters and later pulped. Next, coffee is fermented in dedicated concrete fermentation tanks for an average of 12 hours. During this time, the fermented parchment is agitated several times through the day by way of ceremonial foot-stomping. This is to encourage lower density parchment to float and to clean any residual mucilage off the parchment. Once the parchment is separated into grades, it is given a final post-wash rinse. At this point, coffee is then taken to a pre-drying area where the parchment is hand-sorted removing any insect-damaged, discoloured or chipped coffee. Parchment is then laid out to dry where it is turned on a regular basis throughout the day.

After fermentation, coffee is released into a large serpentine grading channel. This process also separates parchment into different density grades. During the washing process, parchment is continuously agitated to encourage lower density parchment to float and to clean any residual mucilage off the parchment. Once the parchment is separated into grades, it is given a final post-wash rinse. At this point, coffee is taken to a pre-drying area where the parchment is hand-sorted removing any insect-damaged, discoloured or chipped coffee. The parchment is laid out to dry and turned on a regular basis throughout the day for 30 days.

“We found that these varieties like the climate of the Shyira area. Interestingly, they matured faster than the Red Bourbon we are used to growing.

The trees are high yielding as well, which demands good agricultural practices. We maximised this with additional fertiliser and manure application.

The harvest was bountiful considering the number of trees, as well as their level of maturity. I would suggest that we increase the number of these trees grown at Shyira.”

Evariste Hagumimana, manager of Shyira Washing Station

Maximum Impact Coffee

There are multiple aspects of impact to consider. At Raw Material, they are concerned about the impact across three main dimensions, weighted in this order:

1. Economic impact

Enabling economic freedom for people working in coffee. In particular, those for whom coffee is a large proportion of their household income. They focus where improvement in income levels, volatility, or payment timing will most likely have a significant influence on wellbeing. Enabling this economic impact through an improved system is the core focus of our work, measured at both the household and community level.

2. Social impact

Contributing to the development of and sharing of knowledge across all participants in the coffee sector, to enable improved inclusive income opportunities and community wellbeing. For example, working with producers to improve production practices; training cuppers and graders in remote regions to recognise quality early and empower marginalised groups; working with roasters to adopt buying practices that include stable prices and long-term planning.

3. Environmental impact

The long-term sustainability of the coffee sector, both economically and environmentally. Through their work, Raw Material can help develop and share environmentally sustainable practices. These are designed in the context of local constraints, including transition, hidden, and ongoing costs, in order to improve viability and the likelihood of long-term adoption.